What Safety Compliance Means for Your Business

Safety compliance is the ongoing process of meeting workplace safety regulations set by government agencies like OSHA to protect employees from occupational hazards and injuries.

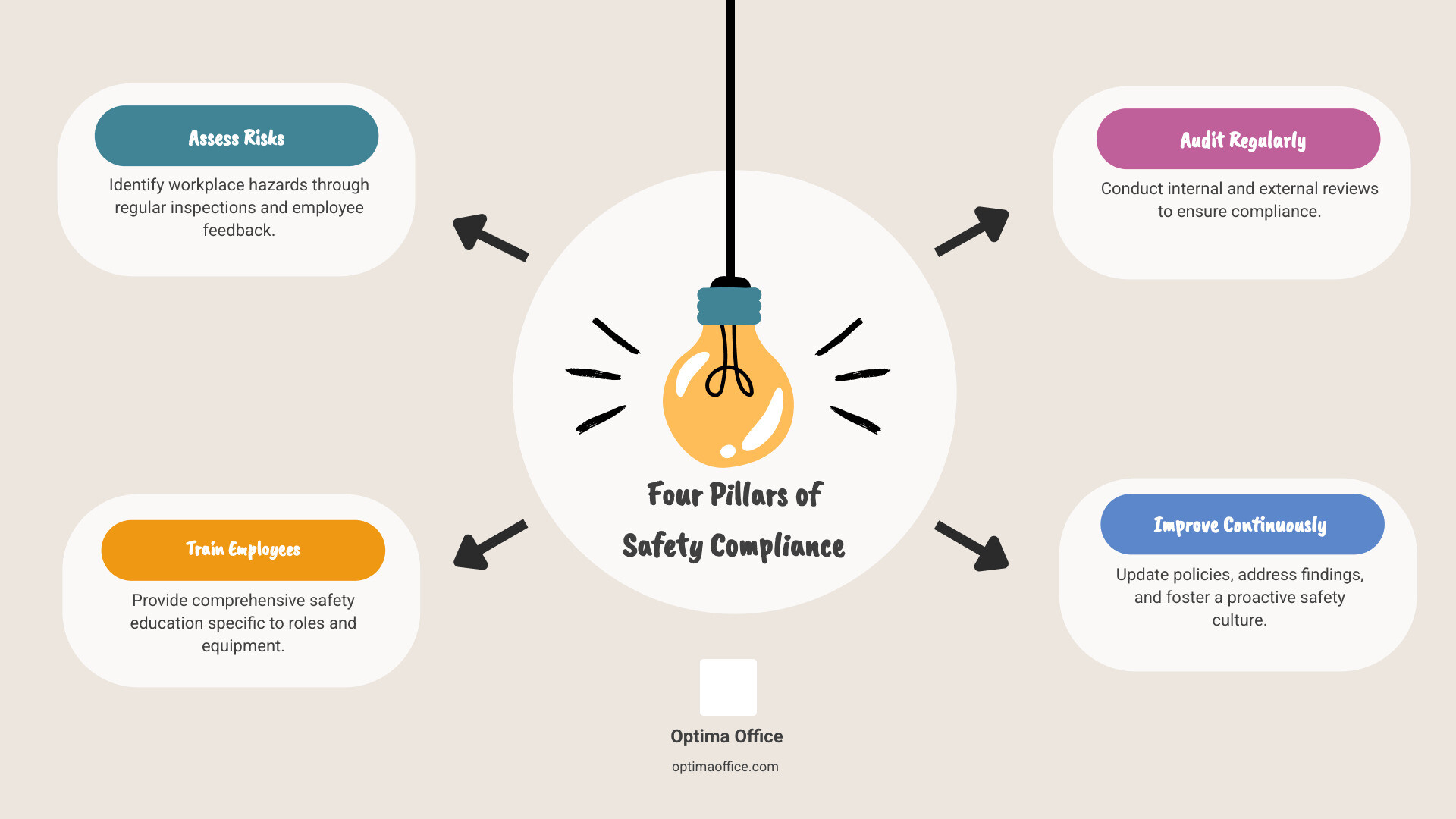

Key Elements of Safety Compliance:

- Regulatory adherence – Following federal, state, and local safety laws

- Hazard prevention – Identifying and eliminating workplace risks

- Employee training – Teaching workers how to stay safe on the job

- Documentation – Maintaining records of policies, incidents, and training

- Continuous improvement – Regular audits and updates to safety programs

Every year, approximately 2.78 million workers die from occupational accidents and work-related diseases worldwide, with an additional 374 million suffering non-fatal injuries. These sobering numbers remind us that workplace safety isn’t just about checking boxes or avoiding fines.

For small and mid-sized businesses, safety compliance can feel overwhelming. You’re already stretched thin managing operations, finances, and growth. Adding complex safety regulations to your plate—especially when staff turnover hits or you’re dealing with a crisis—can seem impossible.

But here’s the good news: safety compliance doesn’t have to be complicated. With the right framework, it becomes a manageable part of your operations that actually protects your business while keeping your people safe.

Whether you run a professional services firm, manage a manufacturing facility, or oversee a healthcare practice in San Diego or Southern California, understanding safety compliance is essential. It’s not just about avoiding OSHA penalties (though that matters). It’s about creating a workplace where employees feel protected, productivity thrives, and your business reputation stays strong.

Understanding the Foundations of Safety Compliance

At its core, safety compliance is about safeguarding the most valuable asset any business has: its people. It’s the continuing process of meeting regulations that ensure the occupational health and safety of employees, reducing hazards and risks within a workplace. While the primary goal is to keep workers safe, adhering to these rules is also a legal imperative.

The stakes are incredibly high. Each year, an estimated 2.78 million workers die from occupational accidents and work-related diseases, while an additional 374 million workers suffer from non-fatal occupational accidents. These statistics are a stark reminder that neglecting safety compliance can have devastating human and financial consequences. The saying that “safety regulations are written in blood” is a sobering reminder of their necessity.

Beyond the moral obligation to protect our employees, there are significant legal and financial ramifications for non-compliance. Failure to adhere to regulations can result in injuries, employee sick leave, costly lawsuits, substantial penalties, and hefty worker compensation payouts. For instance, the Occupational Safety and Health Act requires employers to comply with hazard-specific safety and health standards. Moreover, employers must also provide a workplace free from recognized hazards likely to cause death or serious physical harm, as mandated by the General Duty Clause.

Key Regulatory Bodies

In the United States, safety compliance is primarily overseen by federal and state agencies. The Occupational Safety and Health Administration (OSHA) is the federal agency responsible for creating and enforcing workplace safety standards. Established by the Occupational Safety and Health Act of 1970, OSHA’s mission is to ensure that employees work in a safe and healthful environment by setting and enforcing standards, and by providing training, outreach, education, and assistance.

While OSHA sets federal guidelines, many states, including California, operate their own state-specific occupational safety and health programs, often referred to as “state plans.” These state plans are approved by federal OSHA and must be at least as effective as federal OSHA standards. In California, this agency is known as Cal/OSHA. California regulations are often considered among the strictest in the nation regarding safety compliance, necessitating specialized expertise for businesses operating here.

Other federal bodies include the Mine Safety and Health Administration, which regulates safety in mining operations. Our focus, however, remains on the regulations pertinent to the diverse businesses we serve across San Diego and Southern California, primarily under OSHA and Cal/OSHA.

Why It’s More Than Just Avoiding Fines

While avoiding fines and penalties is a clear motivator for safety compliance, the benefits extend far beyond legal and financial avoidance. Proactive safety compliance is a strategic business asset that contributes to overall success and sustainability.

- Employee Morale and Retention: When employees feel safe and valued, their morale improves significantly. A commitment to safety compliance demonstrates that we care about our team’s well-being, fostering a positive work environment and reducing turnover. This, in turn, helps us retain skilled talent, which is crucial for business continuity and growth.

- Increased Productivity: A safe workplace is a productive workplace. Fewer accidents mean less downtime, fewer sick days, and a more consistent workflow. Employees who aren’t worried about hazards can focus better on their tasks, leading to higher efficiency and output.

- Improved Brand Reputation: Our commitment to safety compliance reflects positively on our brand. It signals to clients, partners, and the community that we are responsible and ethical employers. This can open doors to new business opportunities and strengthen our standing in the market.

- Reduced Insurance Costs: A strong safety record can lead to lower workers’ compensation premiums and other insurance costs. Insurers often offer discounts to businesses that demonstrate effective risk management and a low incidence of workplace accidents.

- Attracting Top Talent: In today’s competitive job market, potential employees look for more than just a paycheck. A reputation for prioritizing safety makes our business a more attractive place to work, helping us recruit high-caliber individuals who value a secure and healthy environment.

- Business Continuity: Major accidents can halt operations, damage equipment, and lead to significant financial losses. Robust safety compliance acts as a preventative measure, protecting our physical assets and ensuring that our business can continue to operate smoothly without unexpected interruptions.

Investing in safety compliance is an investment in our people and our future. It cultivates a culture of care, resilience, and operational excellence that drives long-term success.

The Essential Components of a Robust Safety Compliance Program

Building a robust safety compliance program isn’t a one-time task; it’s an ongoing commitment that requires a structured approach. A comprehensive program integrates policies, training, and continuous monitoring to create a safe and healthy workplace.

At Optima Office, we understand that small and mid-sized companies need a mixture of accounting and HR talent to effectively run their operations. Our HR advisory services are designed to help you steer the complexities of safety compliance and implement these essential components. This includes developing and maintaining HR Compliance programs that protect both your employees and your business.

Policies, Procedures, and Documentation

The foundation of any strong safety compliance program lies in clear, well-documented policies and procedures. These written guidelines serve as our roadmap for safety, outlining expectations, responsibilities, and protocols.

- Written Policies: We must have clear, concise policies covering all relevant safety areas, from hazard communication to emergency response. These policies should be custom to our specific workplace and industry. Having them readily available, perhaps within The Importance of an Employee Handbook, ensures everyone understands their role in maintaining a safe environment.

- Clear Communication Channels: Policies are only effective if they are communicated and understood. We need to establish clear channels for disseminating information, conducting regular safety meetings, and ensuring employees can ask questions and provide feedback without fear of reprisal.

- Document Control: Maintaining meticulous records is crucial for safety compliance. This includes documentation of policies, training records, incident reports, audit findings, and corrective actions. Proper document control ensures that information is accurate, up-to-date, and easily accessible during inspections or in the event of an incident.

- Incident Reporting Procedures: A critical component is a clear and accessible procedure for reporting all incidents, near-misses, and hazards. This allows us to investigate, identify root causes, and implement preventative measures to avoid future occurrences.

Training, Education, and Competency

Even the best policies are ineffective without proper training. Education empowers our employees to identify hazards, follow safe procedures, and respond appropriately in emergencies. OSHA has created hundreds of standards, and many of these include specific training requirements.

Here are some essential training topics that often apply to businesses in Southern California:

- OSHA 10 & OSHA 30: These courses provide comprehensive instruction on general safety and health hazards. OSHA 10 is for entry-level workers, while OSHA 30 is designed for supervisors and those with safety responsibilities.

- HAZMAT/HAZWOPER: For workplaces dealing with hazardous materials, Hazardous Waste Operations and Emergency Response (HAZWOPER) training is critical. This could involve 40-hour, 24-hour, or 8-hour refresher courses, depending on the role and exposure.

- Role-Specific Training: Training must be custom to the specific hazards and tasks associated with each job role. This might include fall prevention for construction, bloodborne pathogen training for healthcare, or lockout/tagout procedures for manufacturing. Our HR advisory services can help identify and manage these HR Required Training needs.

- Designating a Competent Person: For certain hazards, OSHA requires the designation of a competent person. This is an employer-designated individual with the knowledge and authority to identify, control, and correct workplace hazards. This individual plays a vital role in day-to-day safety management.

- Documenting All Training: We must maintain detailed records of all safety training, including dates, topics covered, attendees, and trainer qualifications. This documentation is essential for demonstrating safety compliance during audits.

Audits, Inspections, and Continuous Improvement

A truly robust safety compliance program is never static. It involves regular checks, evaluations, and a commitment to continuous improvement.

- Regular Site Assessments: We should conduct routine inspections of our facilities and job sites to identify potential hazards, evaluate the effectiveness of existing controls, and ensure adherence to safety protocols. These can be formal or informal, but consistency is key.

- Internal vs. External Audits: Internal audits, performed by our own team members (or with the help of our HR advisors), allow us to proactively identify gaps. External audits, conducted by third-party experts, provide an objective assessment and can often uncover issues we might have overlooked. Our HR Compliance Audit services can be invaluable here.

- Corrective Action Plans: When audits or inspections reveal deficiencies, we must develop and implement clear corrective action plans. These plans should specify what needs to be done, who is responsible, and by when.

- Employee Feedback Loops: Our employees are often the first to notice safety issues. We need to encourage them to report hazards and provide feedback on safety procedures. Creating an environment where they feel comfortable sharing concerns is paramount.

- Reviewing Incident Logs: Analyzing incident reports and near-misses is a powerful tool for identifying trends and systemic issues. This data allows us to refine our policies and training, preventing similar incidents in the future.

By diligently implementing these components, we can build a strong safety compliance framework that not only meets regulatory requirements but also fosters a proactive safety culture throughout our organization.

Safety in Action: Industry-Specific Needs and Scenarios

While the core principles of safety compliance remain universal, their application varies significantly across different industries and workplaces. What constitutes good safety practice in an office differs greatly from a construction site or a medical facility.

Understanding these nuances is crucial for effective safety compliance. It’s about tailoring our approach to the specific hazards and risks present in our environment, ensuring that our efforts are both relevant and effective. This allows us to move beyond generic guidelines and develop a proactive culture of hazard identification and prevention.

Examples of Good vs. Bad Safety Compliance

Let’s look at some practical scenarios to illustrate the impact of safety compliance.

Good Compliance Scenario (Manufacturing in Southern California):

Consider a precision manufacturing facility in San Diego that uses heavy machinery and various chemicals.

- Proactive Measures: The company conducts weekly safety walkthroughs, involving line supervisors and a designated competent person. They have clearly defined lockout/tagout procedures for machine maintenance, and all employees receive annual training on these procedures, as well as hazard communication and emergency response. They provide high-quality personal protective equipment (PPE) custom to specific tasks and ensure it’s regularly inspected and replaced.

- Outcome: The facility boasts a low accident rate. Employees feel empowered to report near-misses, leading to continuous improvements. When Cal/OSHA conducts an inspection, the company can easily present comprehensive training records, maintenance logs, and incident reports, demonstrating full safety compliance. This contributes to lower insurance premiums and a reputation for being a responsible employer, making it easier to attract skilled labor.

Bad Compliance Scenario (Construction Site in Los Angeles):

Imagine a small construction company operating in Los Angeles, cutting corners to meet tight deadlines.

- Negligence: The company provides minimal fall protection equipment, and it’s often poorly maintained. Safety training is perfunctory, with new hires receiving little more than a quick rundown of rules. There’s no designated competent person for fall hazards, and supervisors often overlook unsafe practices to keep work moving. Scaffoldings are not regularly inspected, and emergency exits are sometimes obstructed.

- Outcome: A worker falls from a faulty scaffolding due to inadequate fall protection and lack of training, resulting in severe injuries. This leads to an immediate Cal/OSHA investigation, significant fines, a costly workers’ compensation claim, and potential lawsuits. Work on the site grinds to a halt, causing project delays and reputational damage. Employee morale plummets, and the company struggles to find new skilled workers, impacting its long-term viability. The human cost, of course, is immeasurable.

These examples highlight that diligence in safety compliance not only protects lives but also safeguards the financial health and reputation of our business.

Unique Industry Requirements

The nature of hazards varies widely, meaning safety compliance must be customized.

- Construction Safety: Construction sites are inherently dynamic and hazardous. Regulations under OSHA 1926 | Occupational Safety and Health Administration cover everything from fall protection (the leading cause of fatalities) and scaffolding safety to excavation and trenching, electrical safety, and silica exposure. In Southern California, specific requirements for heat illness prevention are also critical, especially for outdoor workers.

- Healthcare Safety: In medical, dental, and veterinary offices, safety compliance focuses on preventing exposure to bloodborne pathogens, infectious diseases, and hazardous chemicals. HIPAA compliance also becomes critical for protecting patient privacy. Annual training on these topics is often legally required, and due to the specific needs of this sector, it’s a highly specialized area of compliance.

- General Industry/Office Safety: Even in what seems like a low-risk office environment, safety compliance is essential. OSHA 1910 | Occupational Safety and Health Administration covers general industry standards, including fire prevention, emergency egress, electrical safety, and machine guarding (for offices with equipment like shredders or printers).

- Ergonomics: For office-based businesses, ergonomics is a significant area of safety compliance. Poor workstation setup can lead to musculoskeletal disorders, repetitive strain injuries, and lost productivity. Proactive ergonomic assessments and adjustments are key.

- Workplace Violence Prevention: Sadly, workplace violence is a growing concern. In California, new legislation like California SB 553 Workplace Safety mandates specific requirements for employers to prevent and respond to workplace violence. This includes developing a Workplace Violence Prevention Plan (WVPP), which is a critical aspect of safety compliance for many California businesses. We’ve written extensively on this topic, including Preventing Workplace Violence Starts With a Plan and WVPP What You Need to Know.

Our HR advisory services at Optima Office are adept at helping businesses in Southern California identify and address these unique industry requirements, ensuring that your safety compliance program is comprehensive and effective.

Leveraging Technology and Proactive Strategies for Workplace Safety Compliance

In today’s business environment, managing safety compliance efficiently requires more than just binders full of paperwork. Technology and proactive strategies are changing how we approach workplace safety, making it easier to maintain compliance, reduce risks, and foster a safer culture.

The Role of Technology in Modern Safety

Technology offers powerful tools to streamline our safety compliance efforts, moving us from reactive problem-solving to proactive prevention.

- Digital Recordkeeping: Gone are the days of overflowing filing cabinets. Safety management software allows us to digitally store all safety compliance documents—policies, training records, incident reports, audit findings, and certifications. This ensures easy access, better organization, and improved data security.

- Automated Reporting and Analytics: Many platforms offer automated reporting features, generating insights from incident data, inspection results, and training completion rates. This allows us to identify trends, pinpoint high-risk areas, and make data-driven decisions to improve safety.

- E-learning Modules and Online Training Platforms: Online training platforms, like those offered by the OSHA Education Center with over 150 online compliance programs, provide flexible and accessible learning opportunities. Employees can complete required training at their own pace, from any internet-connected device, minimizing disruption to work schedules. This is particularly beneficial for businesses with diverse workforces or multiple locations across Southern California.

- Mobile Apps for Inspections and Checklists: Mobile safety compliance apps allow workers and supervisors to conduct inspections, complete checklists, and report hazards directly from their smartphones or tablets. This provides real-time data, improves accuracy, and facilitates faster corrective actions. Some companies even offer proprietary inspection apps for timely and quality reports.

- Workflow Automation: Integrating safety compliance into our operational workflows using automation software can ensure that safety checks are performed, documents are updated, and training reminders are sent automatically. This reduces administrative burden and minimizes the chance of oversight.

- Virtual Reality (VR) Training: While perhaps more advanced, VR is emerging as a powerful tool for realistic, hands-on safety training, allowing employees to practice emergency procedures or hazardous tasks in a safe, simulated environment.

Improving Your Business’s Safety Compliance Efforts

Moving beyond basic adherence, we can adopt several proactive strategies to continuously improve our safety compliance program.

- Proactive vs. Reactive Approach: Instead of waiting for an incident or an inspection to spur action, we should strive for a proactive approach. This involves regularly assessing risks, anticipating potential hazards, and implementing preventative measures before problems arise. A proactive approach is an asset to any business, fostering a culture where safety is ingrained, not just enforced.

- Leadership Buy-in: Strong leadership commitment is fundamental. When management visibly prioritizes safety compliance, it sets the tone for the entire organization. Leaders must champion safety initiatives, allocate necessary resources, and hold themselves and their teams accountable.

- Employee Involvement: Our employees are our eyes and ears on the ground. Encouraging their active participation in safety committees, hazard identification, and policy development fosters a sense of ownership and ensures that safety measures are practical and effective. Empowering employees to report hazards without fear of reprisal is crucial.

- Staying Current with Regulations: Safety compliance regulations are not static; they evolve. We must stay informed about new rules, updates, and proposed changes, especially those from Cal/OSHA, which often leads the way in new safety mandates. OSHA’s Regulatory Agenda is a valuable resource for tracking upcoming regulations.

- Whistleblower Protections: We must ensure that our employees feel safe reporting safety concerns without fear of retaliation. Federal laws, like those referenced on Whistleblower General IndustryConstructionMaritimeAgricultureRecordkeepingWhistleblowerPreambles to Final RulesPreambles informationOther, protect workers who raise legitimate safety issues. A strong culture of psychological safety reinforces our overall commitment to safety compliance.

By embracing these strategies and leveraging available technology, we can build a safety compliance program that is not only robust and efficient but also adaptable to the ever-changing landscape of workplace safety.

Frequently Asked Questions about Safety Compliance

Here are some common questions we often hear about safety compliance and our expert answers.

What is the first step for a small business to become compliant?

The very first step for any small business, especially those in San Diego and Southern California, is to conduct a comprehensive hazard assessment of your workplace. This involves systematically identifying all potential hazards – physical, chemical, biological, and ergonomic – that could harm your employees. Once you understand your specific risks, you can then use resources like OSHA’s Compliance Assistance Quick Start tool to identify common requirements for your industry. Following this, you should develop a basic written safety plan that addresses these identified hazards and outlines your preventative measures. Our HR advisory services can help guide you through this initial assessment and plan development.

How often should safety training be conducted?

The frequency of safety compliance training varies depending on the specific standard and the nature of the work. OSHA requires annual training for many standards, such as bloodborne pathogens for healthcare settings or hazard communication for workplaces using chemicals. However, it’s crucial to understand that training should also occur whenever a new hazard is introduced, new equipment is used, or an employee’s job role changes. Beyond regulatory mandates, it’s a best practice to conduct regular refresher courses and periodic safety meetings to reinforce knowledge and keep safety top-of-mind. Continuously trained employees are better workers, managers, and supervisors, making our workplace safer and more efficient.

What are the major consequences of non-compliance?

The consequences of non-compliance with safety compliance regulations can be severe and multifaceted. They range from significant financial penalties and citations issued by regulatory bodies like Cal/OSHA to, in the most severe cases, criminal charges. Beyond these legal repercussions, non-compliance can lead to devastating and costly workplace accidents, which result in higher workers’ compensation claims, increased insurance premiums, and potential lawsuits. There’s also the immeasurable cost of human suffering and loss of life. Furthermore, non-compliance can severely damage our business’s reputation, harm employee morale, and make it difficult to attract and retain talent, ultimately impacting our long-term profitability and sustainability. The financial impact of avoiding these penalties is significant, as proactive compliance can save businesses millions of dollars over time.

Conclusion

As we’ve explored, safety compliance is far more than a regulatory obligation; it’s a continuous journey and a fundamental blueprint for a secure and successful business. It’s about protecting our people, fostering a positive work environment, and safeguarding our financial health and reputation. The stark reality of workplace accidents, with millions affected globally each year, underscores the critical importance of a proactive and robust approach to safety.

From establishing comprehensive policies and delivering targeted training to conducting regular audits and embracing technological advancements, every step we take towards stronger safety compliance contributes to a more resilient and thriving organization. We’ve seen how good practices lead to increased morale, productivity, and reduced costs, while negligence can result in devastating consequences.

Managing the complexities of safety regulations, especially with the strict standards here in California, can be challenging. This is where the right partnership becomes invaluable. At Optima Office, our expert HR advisory services are dedicated to helping you build and maintain a compliant and secure workplace. We understand that small and mid-sized companies need custom support to maximize profits, minimize risk, and drive enterprise growth, and our HR professionals bring the right expertise and personality fit to solve these problems quickly. Our proprietary five-point system ensures we find the right fit for your business, integrating financial and HR leadership seamlessly.

Ready to build a comprehensive safety plan that protects your team and your business? Learn more about developing a Workplace Violence Protection Plan and other essential safety protocols. Partner with us to achieve true HR Compliance Success and ensure your business is not just compliant, but truly safe and prepared for the future.